A Transport Heritage New South Wales funded project.

One of the impediments to the regular operation of Variotram 2107 at Loftus is its hybrid ‘tram-train’ profile wheels are incompatible with the ‘old’ Sydney point work used at the museum.

The goods line that was used for the original Sydney Light Rail project was not converted to tramway standards – it was left compatible with heavy rail trains. At the time of the projects inception, grain was still being hauled into Pyrmont and the project planning proceeded on the basis that this would continue. So the trams were specified with ‘tram-train’ wheels that allowed the cars to negotiate heavy rail points in a safe manner.

This special wheel profile has a ‘step’ on the wheel back to engage the railway check rails. This gives a wheel with both tramway and railway ‘back-to-back’ measurements.

The old Sydney tramways used raised check rails on points – and the museum has many of these points recovered from locations around Sydney. These check-rails foul the ‘tram-train’ step on the back of the Variotram wheels.

This project, supported by Transport Heritage NSW, is to ‘in place’ mill the wheel backs to remove this step. This will make the wheels compatible with the museum tracks. To this end a Wollongong based specialist engineering firm Leussink Engineering has been engaged to perform this work. Leussink will design and fabricate the tools needed to perform the task and then their machinists will assemble the tool at Loftus and machine the wheels to a suitable profile.

Lifting 2107 to remove the bogies and send them for offsite work is not possible at Loftus at this time, as special ‘lifting bay’ will have to be constructed for the special Variotram jacks. In place wheel milling is the most cost effective method at this time.

One of the first tasks was define exactly what shape the wheels needed to be. Pictured is one of the ‘spare tires’ being measured to assist with creating a specification drawing,. This picture shows the back of a wheel and the ‘tram-train’ step that has to be machined off to make the wheels compatible with ‘old’ style Sydney tramway points.

30th September, 2020

Leussink attended the museum and picked up one of the spare Variotram bogies to take back to their Unanderra works. They will use this bogie to assist with prototyping and testing the machine they need to create to do this work. This means when it comes to the wheels on 2107, they will have already used the machine on this bogie and the operators will have a tested process to follow.

The COVID pandemic has delayed this project considerably, with ‘resourcing’ and supply issues causing multiple delays. This has resulted in the project taking far longer than originally expected.

June 2021

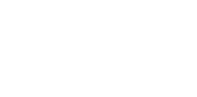

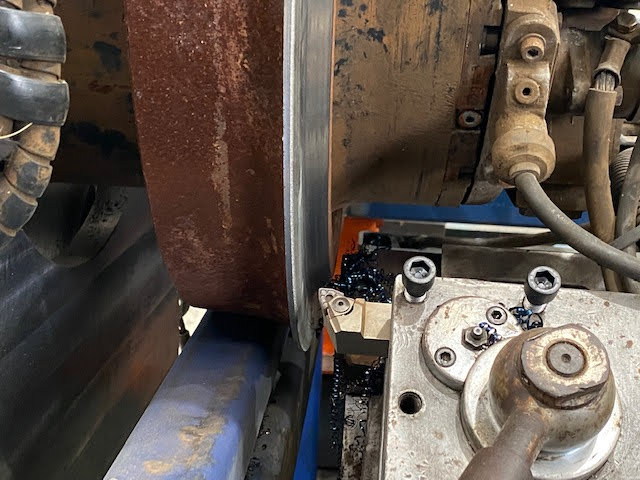

Leussink provided several photos of the ‘mock up’ test setup they built on their factory floor. This equipment will be assembled into the 2 road inspection pit at Loftus.

The bogie that is being used to test the lathe is ex 2106 and has badly worn wheels. The flange is NOT supposed to be that thin. Leussink ‘tested’ the process on that wheel as it was already condemned and would not have mattered if they accidentally took too much off or had other issues with the equipment.

January 2022

Onsite work commenced on Monday 17th of January 2022, starting with the setup of the machine and supporting equipment.

The team from Leussink then machined the wheel back profile on each wheel in turn with the car being shunted to have a wheel in line with the lathe and then the brakes for that wheel being ‘pumped off’ and locked out.

Turning the car

With the 6 wheels on the ‘eastern’ side of the car done by Tuesday the 25th of January, there were two options – dismantle the lathe and reassemble it on the other side of the pit, or turn the car around. Prior investigation indicated that 2107 could safely be taken around Cross Street which would turn the car around. We had intentionally arranged that the ‘eastern’ side would be done first so that the ‘corrected’ wheels would be taking the tightest curve. The actual curvature of Cross Street is larger than the minimum curve radius specification for the Sydney Variotram.

So early on the morning of 26th of January, 2107 was carefully and very slowly driven around Cross Street and then up the museum mainline and reversed at Depot Junction, thus turning the car around.

The Final Run

The next 6 wheels were completed by lunchtime Tuesday the 1st of February 2022, the Leussink crew spending the afternoon dismantling and repacking their equipment.

Still to do.

Now the commissioning of 2107 for museum operation moves into the next phase; the wheel profile was a major item, but not the only one. The list of essential projects needed before a return to service can commence include the following:

- Finish checks and fixes to museum overhead for pantograph operation

- Bleed and check hydraulic brake system

- Adjust the regenerative braking set point. (Has to be lower)

- Replace life expired auxiliary batteries

- Repair airconditioning

- Replace failed saloon lighting drivers

- Repair/replace worn or water damaged seating and flooring

- Repair/reseal roof and windows to prevent water ingress

- Train museum crews in safe and correct operation.

Photos featured on this page are credited to Martin Pinches, Peter Mudie, Daniel Nguyen, Michael Hatton, Jason Leussink and Matthew Geier.